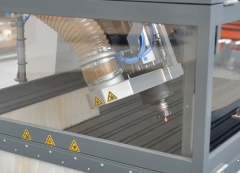

Usually mounted horizontally under the machine gate. It can contain from a few to a dozen or so sockets for CNC tool holders. Tool change is faster than in linear magazines due to the shorter travel time to the tool change point.

It is in the form of a bar and is usually mounted on a machine tool table. It works with spindles equipped with the possibility of automatic tool change. It may contain from a few to several dozen sockets for CNC tool holders. The standard solution on the BPF series machines includes ten tool holders.

This functionality allows for automatic change of the tool used for processing (milling cutter, drill bit, head, etc.). The tool is placed in a special holder (cone), which is taken by the machine spindle from the tool magazine (linear or rotary). Thanks to this solution, there is no need to interrupt the machining and manual change of the tool in the spindle.

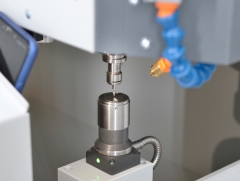

The tool offset sensor allows you to automatically enter the value of the tool length offset which is fixed in the CNC tool cone holder or directly in the spindle chuck. The machine automatically measures the tool length, then corrects the Z-axis coordinate so that the tooltip is at the correct compensation height. On machines equipped with automatic tool change, the measurement can be performed once or before each use. It is also possible to measure the tool after machining to check its parameters and to see if it is damaged or still in the proper working condition.

High-quality cast iron rotary axis for CNC milling machines. It is suitable for processing steel, cast iron, aluminum and other non-ferrous metals, plastics as well as wood and other related materials. The control can take place in the indexed mode or with smooth simultaneous interpolation. The axle is available with a tailstock. Supplied as standard with a 125 mm diameter three-jaw chuck.

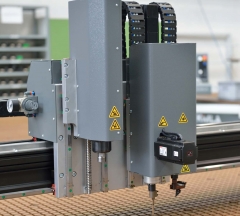

Additional fourth controlled axis. The spindle is tilted around the Y-axis in the range from -95 to 95 degrees. It allows the spindle to be tilted, which allows, for example, for machining side walls of profiles or complex door treatment. This axis is controlled in an indexed manner or with smooth simultaneous interpolation.

Additional controlled axis installed directly on the spindle. Designed for controlling angle aggregates. It enables fixing various types of angle aggregates, eg adapted to circular saws with different disc diameters, fixing cylindrical tools via ER baskets. The possibilities of the rotary axis "C" depend mainly on the assumed angle aggregate. The C axis has the possibility of smooth simultaneous interpolation.

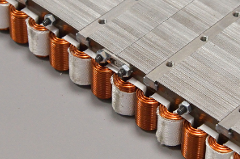

The type of drive used in Kimla machines, characterized by its direct transmission, without the use of gears and conversion of rotary motion to linear. Such a drive consists of a magnetic path, located on the machine body, and an electromagnet that generates an electromagnetic field. Thanks to this solution, the drive does not wear and there is no backlash. For the positioning of the motors themselves, measuring rulers with an accuracy of 0.005 mm / m and a resolution of 0.000001 mm were used. This solution makes the machine very accurate and fast.

This head is characterized by a very high oscillation force. Thanks to this, it is possible to cut materials with very high resistance, as well as materials with a high thickness. Using a suitable blade, it is possible to cut up to 30mm thick rubber. Oscillation speed adjustable ..

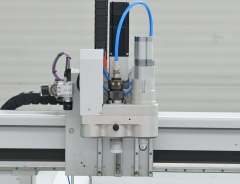

The oscillation drive is carried out by the pressurized air supplied to the machine. The speed of oscillation and force is regulated by controlling the air flow and there is no possibility of precise adjustment from the computer. The head is characterized by a very high oscillation speed, thanks to which it is possible to cut materials with very high efficiency and speed. Because of the way they generate vibrations, their strength is less than ...