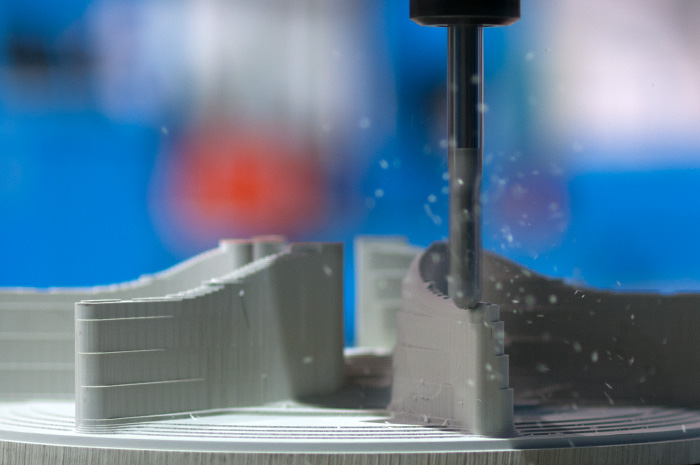

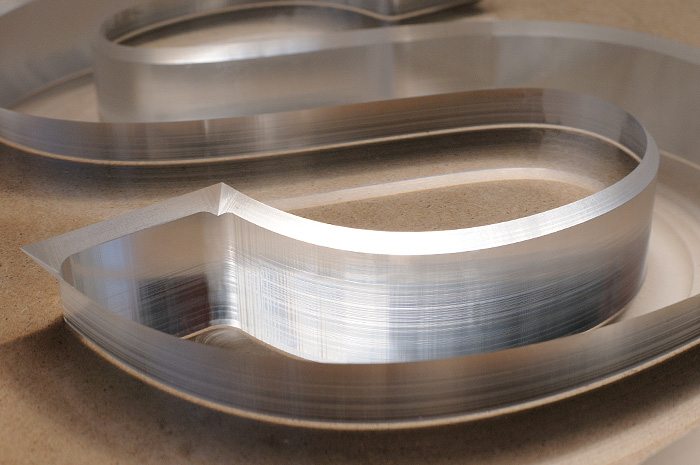

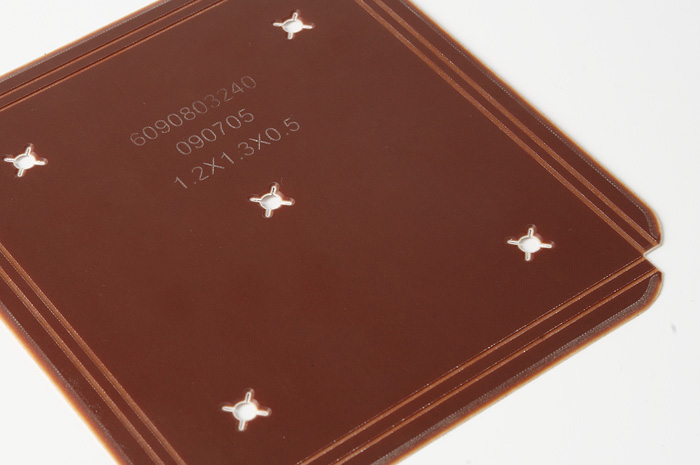

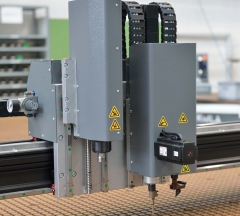

BLACKBIRD CNC milling routers are produced in workspace range: 350x400mm to 2100x2500mm. Z-axis workspace range is 150mm or 200mm. This is absolutely new design which contains many innovative solutions that we have developed on the basis many years of experience. Machines of this series are aimed primarily for advertising agencies, prototyping, manufacturers of packaging and die boards, service shops. All BLACKBIRD machines are equipped with the control system with dynamic analysis of vectors, smooth regulation of the feed speed and spindle rotation. The guides, ball screws, and optical sensors have been fully covered, which provides a minimum of operation activities associated with cleaning and maintenance of the machine.

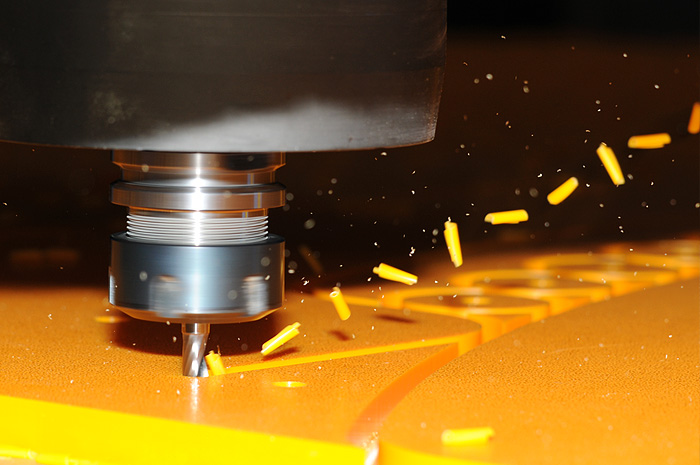

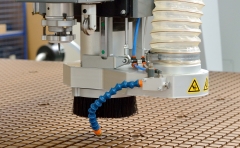

BLACKBIRD routers are available in a few versions. The most popular machine in this group is the machine with the equipment presented in the picture: with a 24000 rpm spindle without automatic tool changing (ATC) and with a T-slot table.

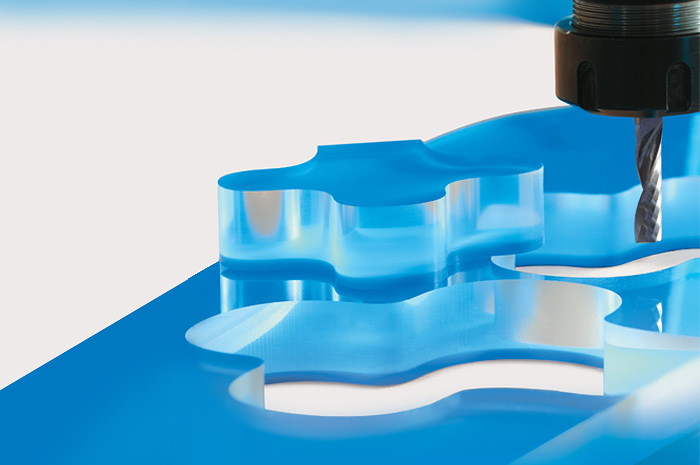

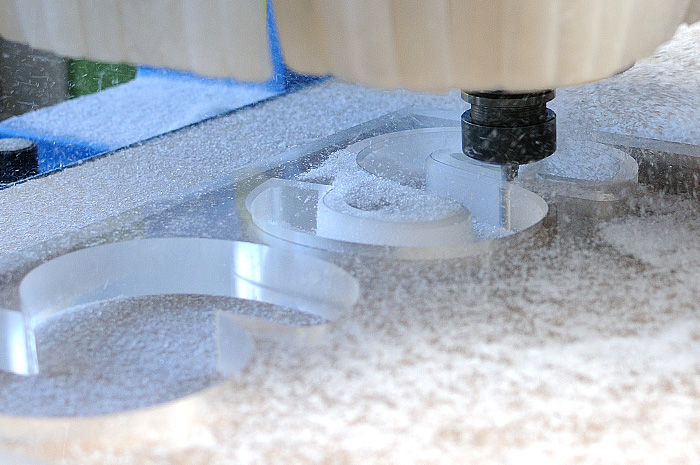

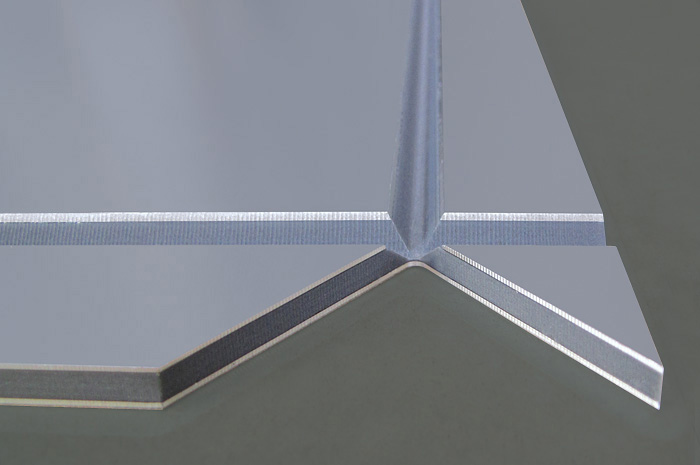

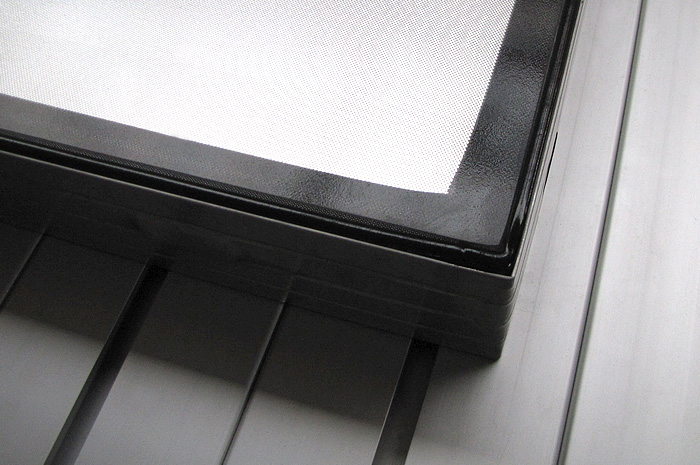

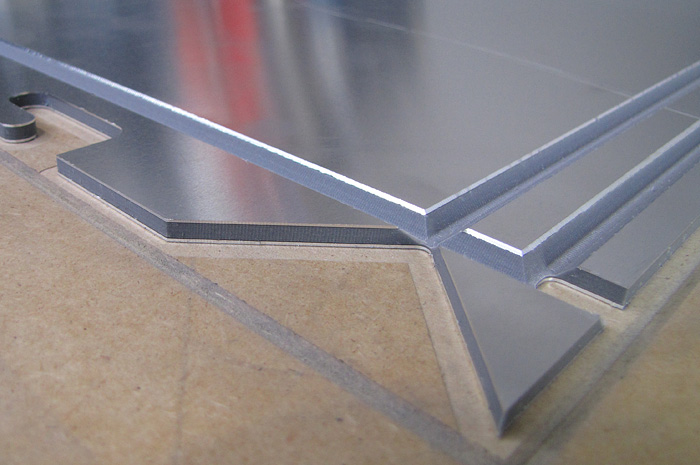

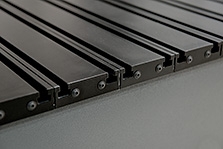

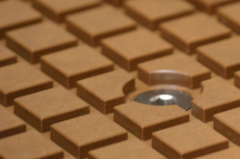

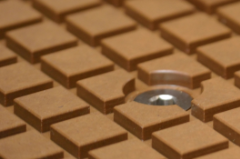

T-slot tables, made of anodized aluminum, greatly facilitate mounting materials. The second option is a vacuum table, which is ideal for fixing large sheets of cardboard, paper plates, plastic, wood, aluminum sheets, and others. HDF plates are used as an intermediate layer between the table and the material . Being breathable, the plates are suitable for this purpose perfectly, so the material lying on them is attached. You can cut parts through without worrying about any damage to the table. When damaged, the plates may be re-ground or replaced with new ones. The advantage is that they are cheap and readily available.

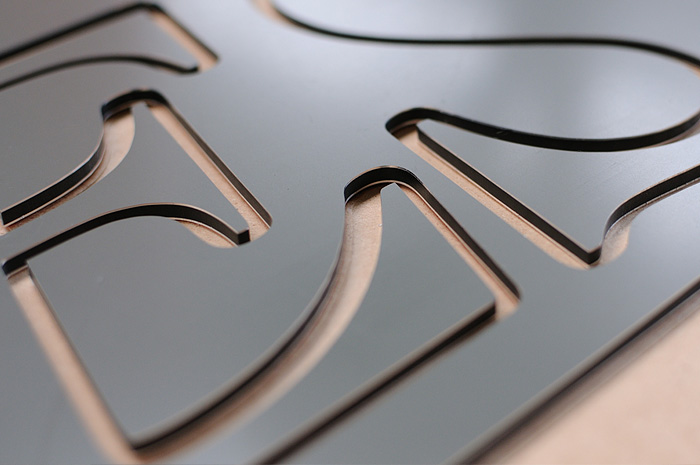

An alternative to the spindle without replacing is the spindle with automatic tool changing (ATC) with a tool storage. It will improve and shorten the processing time requiring the use of multiple tools.

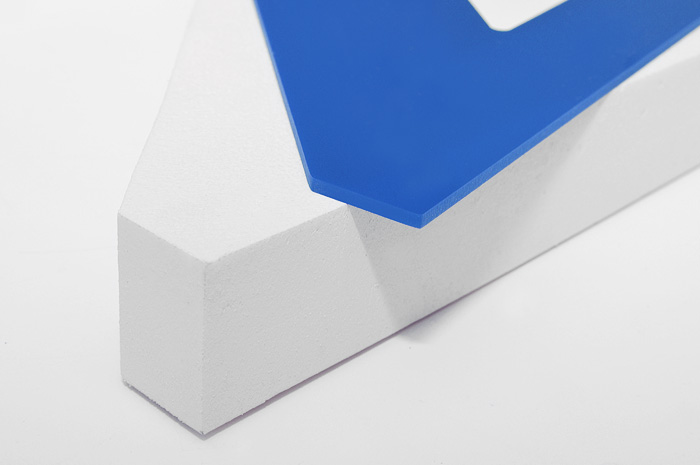

An active head with an oscillating knife and a creasing wheel can be used instead of the spindle. It is ideal for work in the paper, carton, cardboard, rubber, leather, fabrics and other soft materials. It allows you to perform packaging prototypes before making the punching die, to cut small and medium series of gaskets, test patterns for shoes, etc. The cutting-creasing head can also be ordered as a removable accessory fitted to the spindle.

| Work area dimenssions [mm] | Width | 500, 700, 1000, 1200, 1500, 2100 |

|---|---|---|

| Lenght | 400, 700, 800, 1000, 1500, 2000, 2500 | |

| Z axis range | 150, 200 | |

| Spindles | 24 000 rpm | 1 kW, 1.5 kW, 2.1 kW, 2.5 kW |

| 60 000 rpm | 0.8 kW, 0.97 kW, 2.1 kW | |

| Control system | Digital AC Servo Drives | |

| Table type | T-slot table | |

| Vacuum table | ||

| Hybrid table | ||

| Oil mist cooling | Automatic | |

|---|---|---|

| Manual | ||

| Heads | Active, oscillating knife | |

| Creasing | ||

| Active with knife | ||

| Knife for cutting film | ||

| Other heads | Writing | |

| Pouring | ||

| Scanner | Touch | |

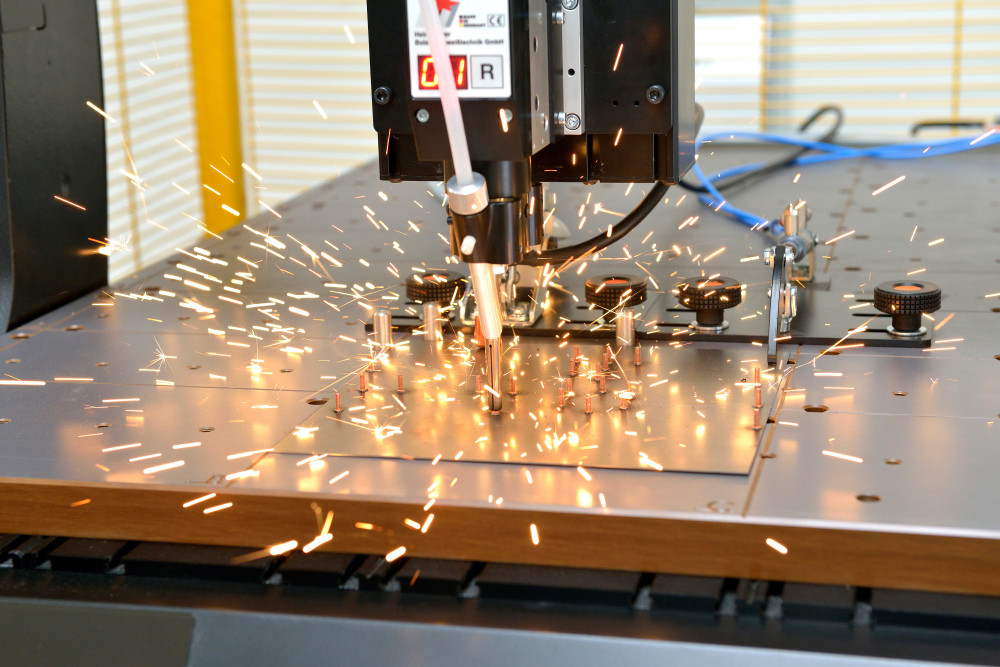

| Laser | ||

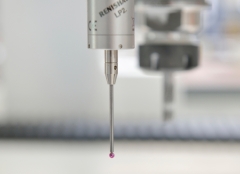

| Automatic tool changing | (for spindles running at 60 000 rpm) | |

| Control cabinet with computer | ||

| Presser foot, Suction foot | ||

| Dust extraction system | ||

| Camera sighting system | ||