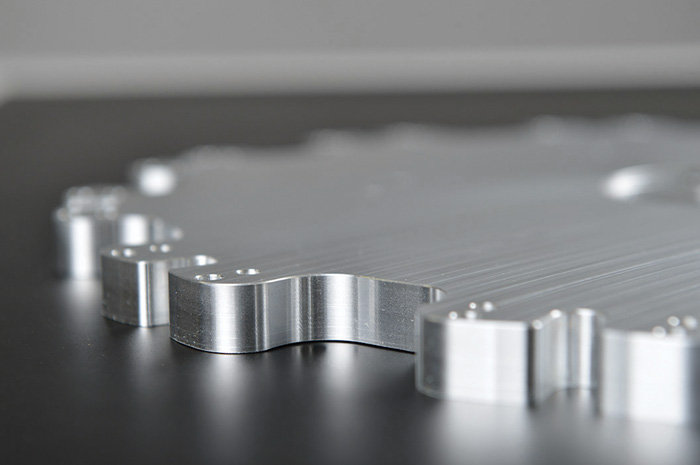

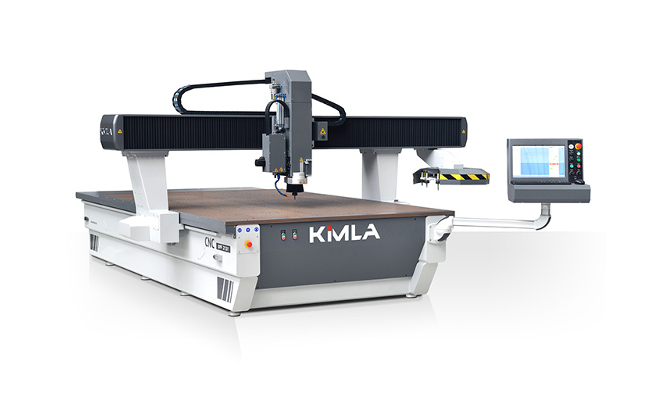

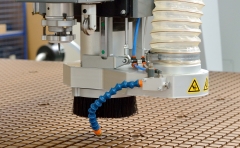

Large area milling machines are devices designed for heavy production works, featuring high efficiency, and robust and stable construction.

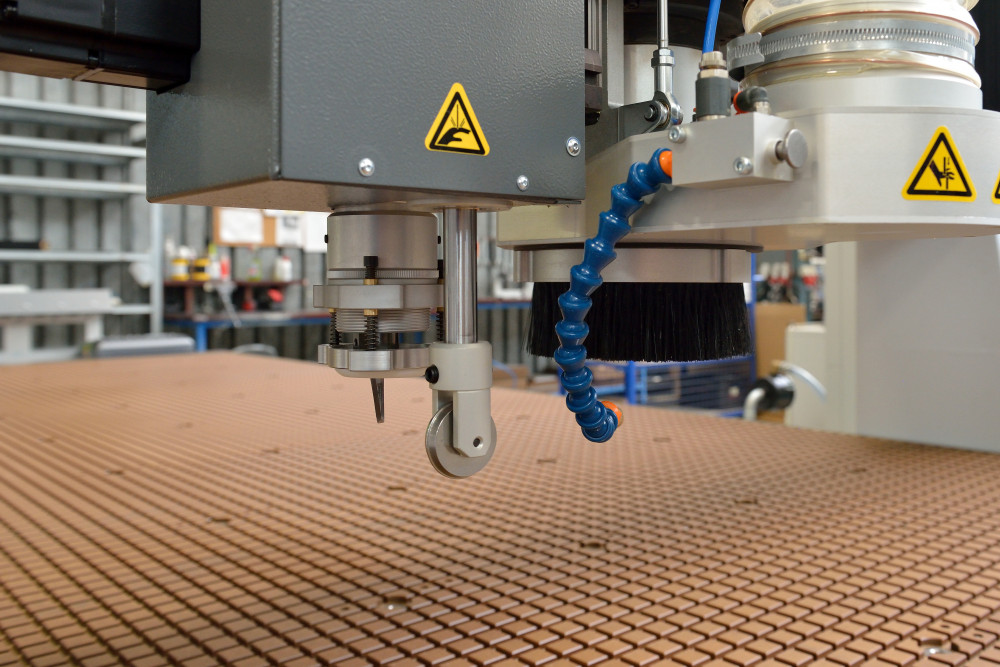

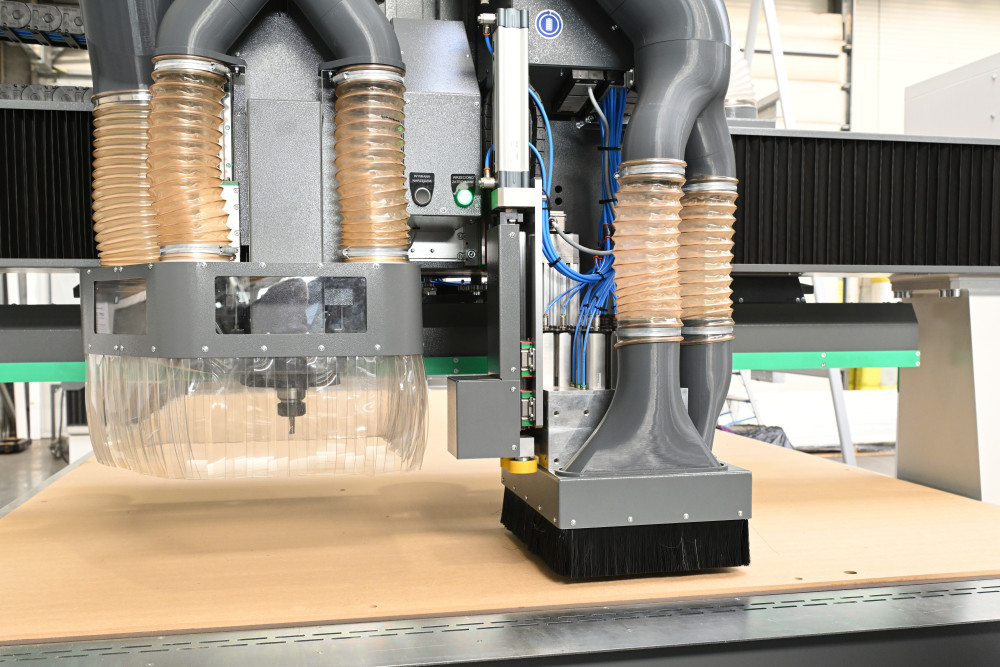

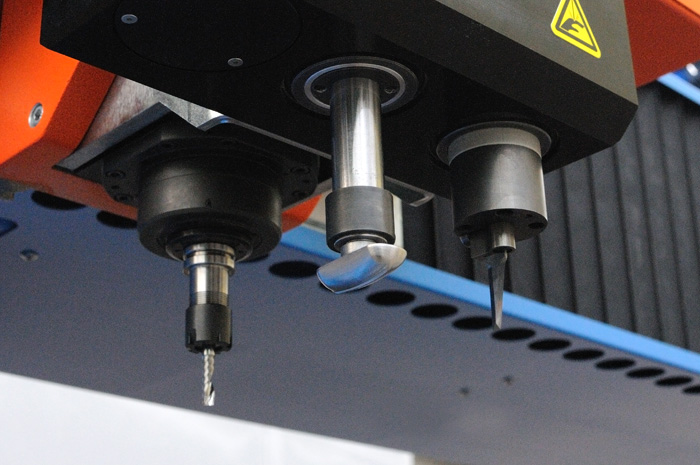

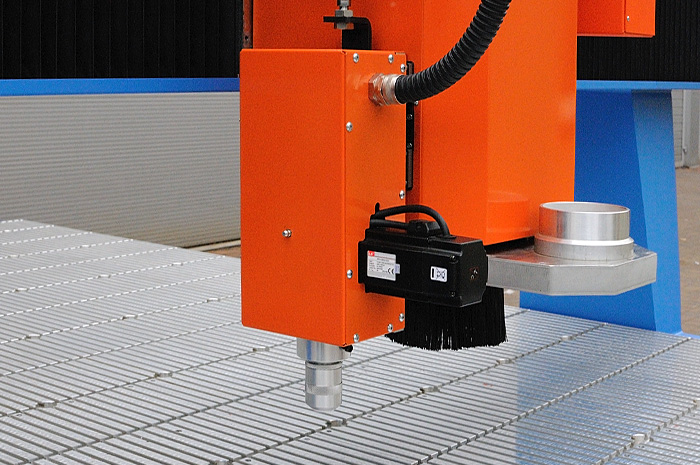

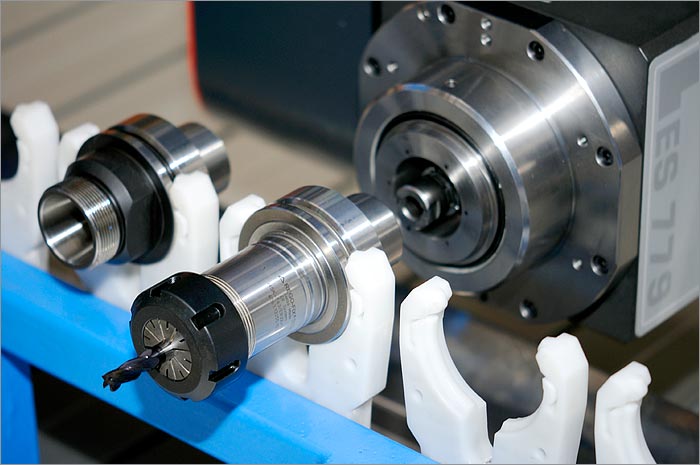

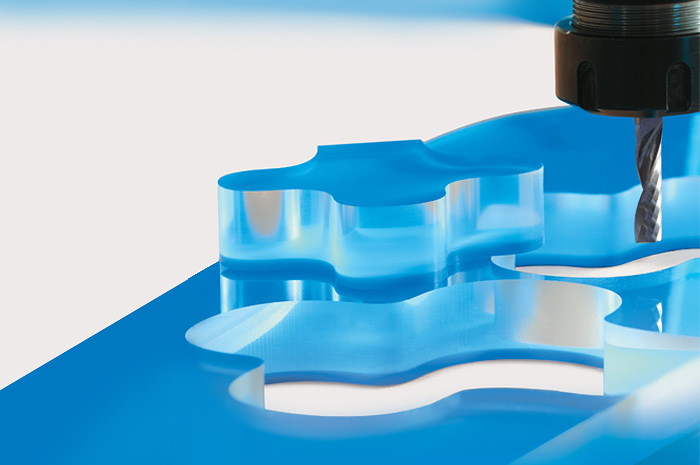

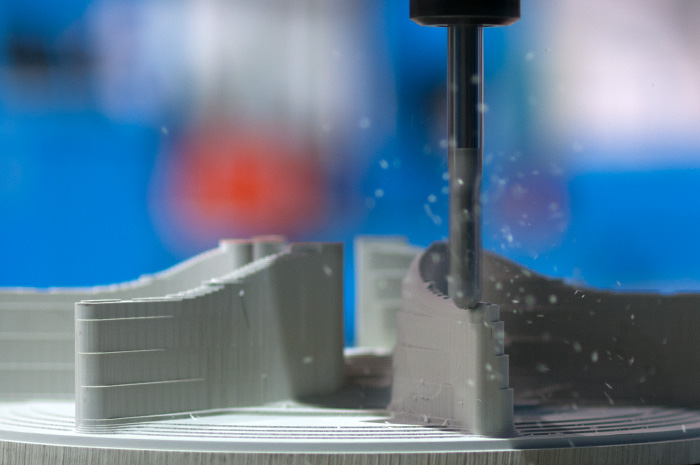

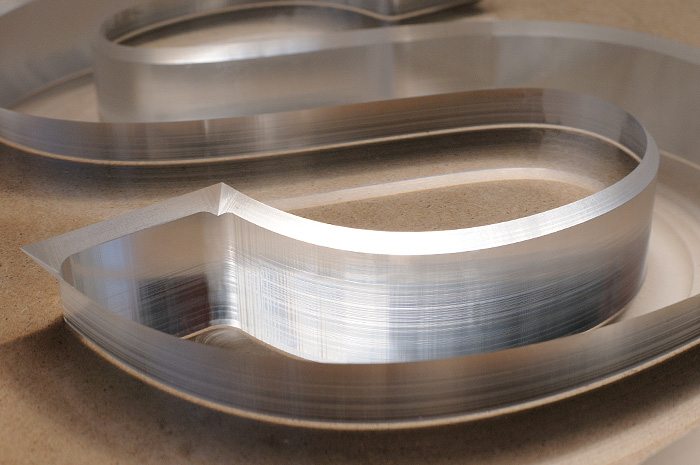

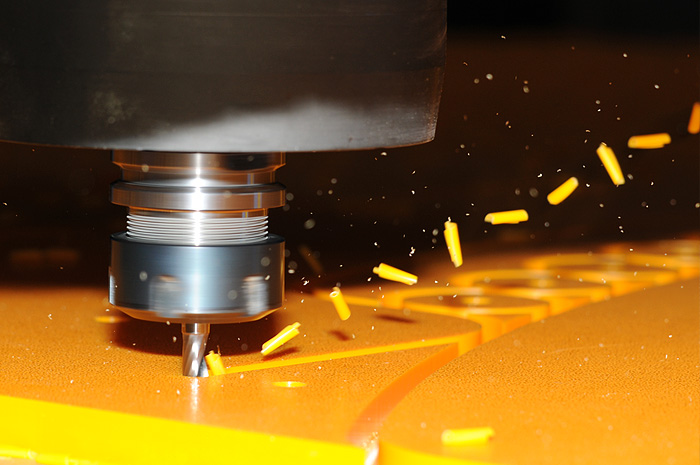

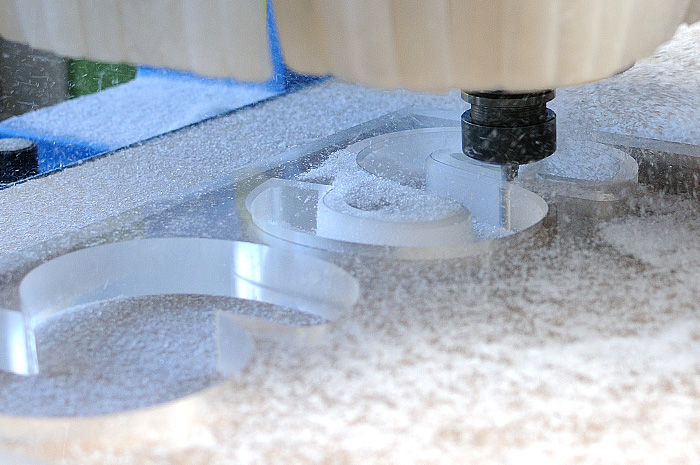

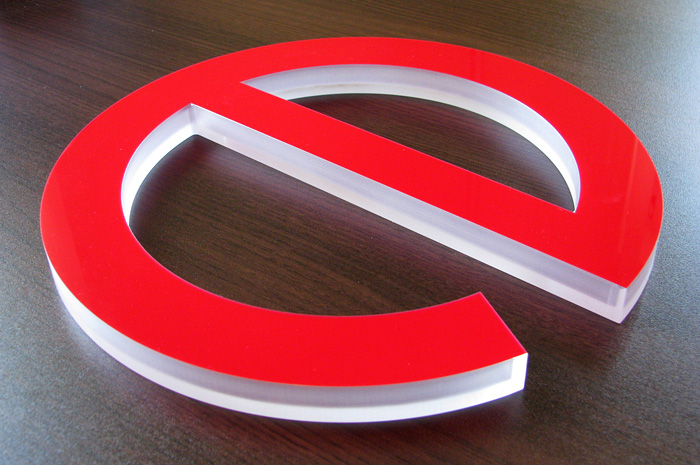

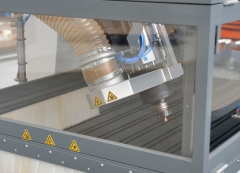

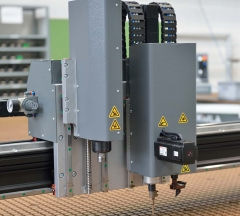

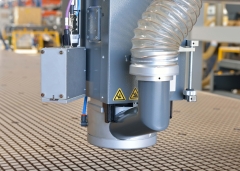

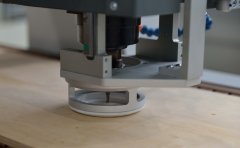

The milling machines perform both flat (e.g. cutting shapes out of sheet metals, drilling on the basins of two-dimensional drawing), and three-dimensional milling tasks (e.g. preparation of models for casting, laminating, thermal forming). In milling works, in which a number of tools are used, the routers are equipped with systems of automatic tool changing with storage. Automatic tool changing is available in linear or rotational version, depending on the size of the table and the customer's needs in terms of machine efficiency. Industrial machines are equipped with suction foot or suction hood. It is an effective means of dust extraction from the milling station. Suction hood may be set automatically on different heights, depending on the lenght of the attached tool, so that secure the most effective dust extraction.

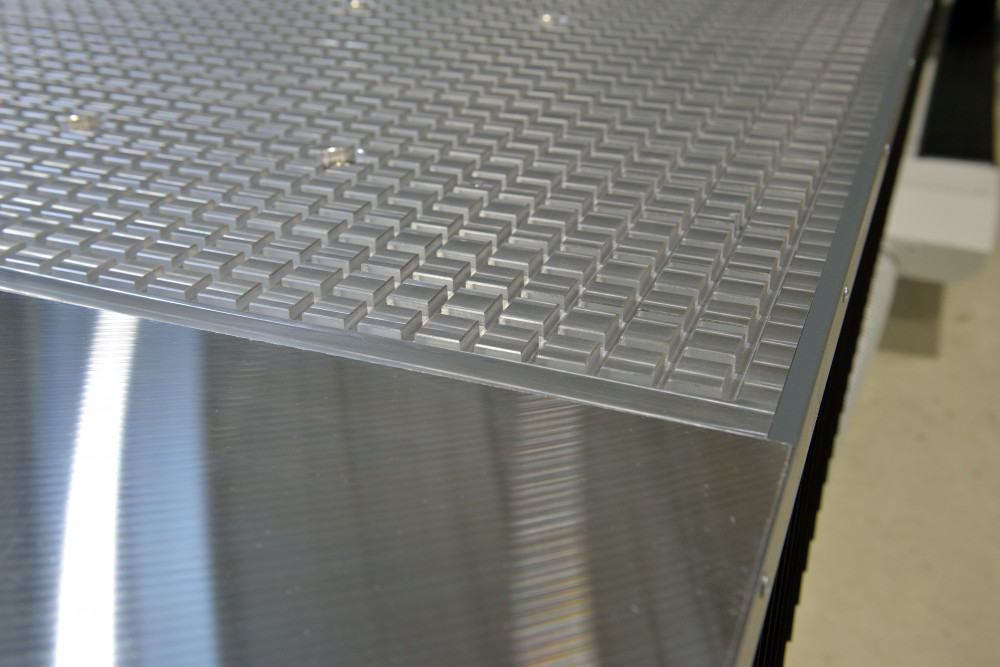

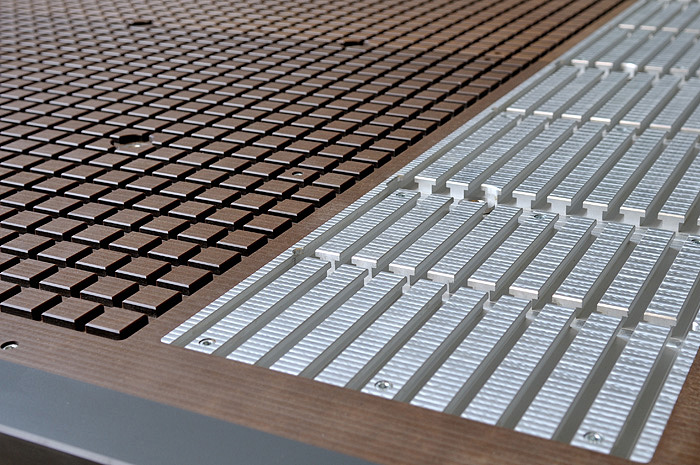

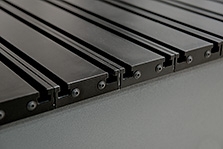

Large area milling machines tables may be executed in the basic version, that is T-slot tables. The most common, however, are vacuum tables, facilitating very strong fixation of large format materials, without the need to use mechanical fixation.

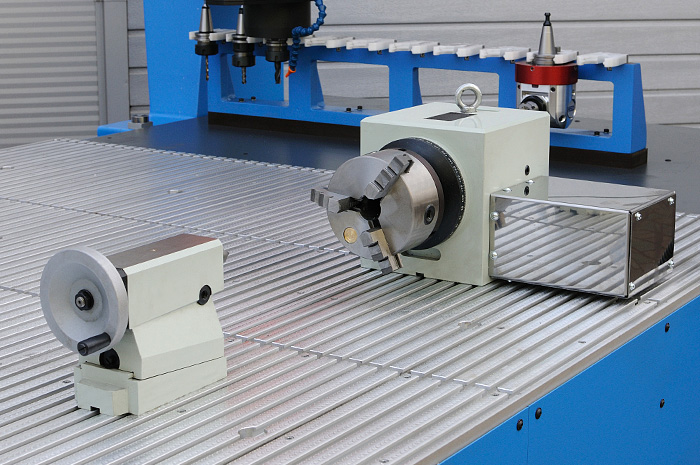

If a vacuum tables does not provide sufficient fixation, we provide our customers with hybrid tables. It is a table with very dense T-slots, to which vacuum is supplied. Owing to this, there is a possibility of adhering the large format elements by suction, as well as screwing in smaller elements, fixation devices or additonal equipment, e.g. rotary axis.

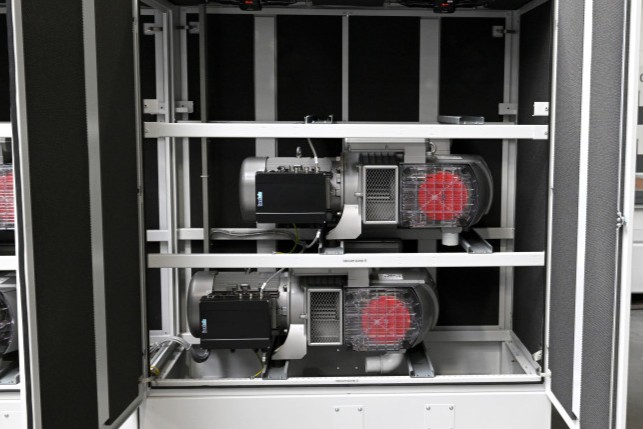

As a standard, vacuum tables are equipped with one or two vacuum pumps from Becker company, featuring efficiency of 250m3/h. This solution brings both high performance and low noise emission.

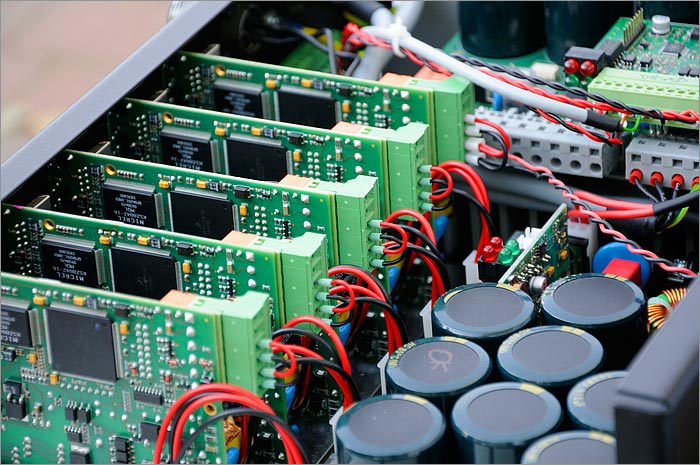

Large area milling machines are always executed in configuration with travelling gantry, with double-sided drive, servomotors and electronic compensation unit of the gantry angle.

Kimla company manufactures milling machines not only in standard version, but also in a special version with pneumatic conveyor, with automatic loading and automatic unloading.

| Working area dimensions [mm] | Width | 1500, 1600, 2100, 2600, 3100 ... |

|---|---|---|

| Lenght | 2100, 2500, 3100, 4100, 5100, 6100, 7100 ... | |

| Z axis range | 200, 300, 400, 500, 600, 700 ... | |

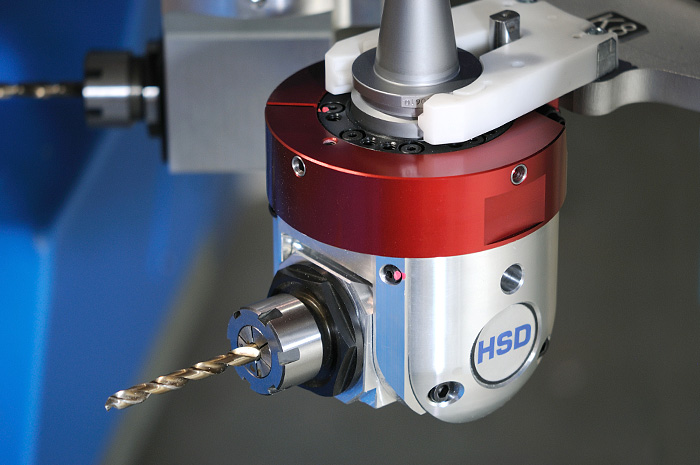

| Spindles | 24 000 rpm | 7 kW, 9 kW, 12 kW, 14 kW, 16 kW, 18 kW, 20 kW |

| 40 000 rpm | 5 kW | |

| 50 000 rpm | 3 kW | |

| Cooling | Air Refrigerating unit | |

| Control system | Digital AC Servo Drives | |

| Table type | T-slot table | |

| Negative pressure table | ||

| Vacuum table | ||

| Hybrid table | ||

| Automatic tool changing (ATC) | no change | |

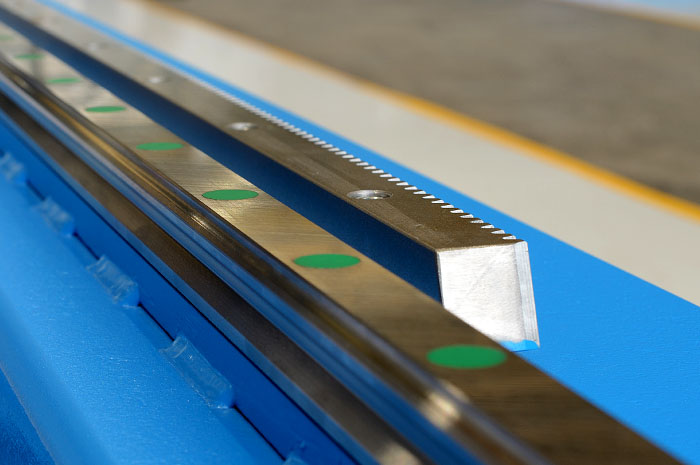

| linear storage | ||

| rotating storage | ||

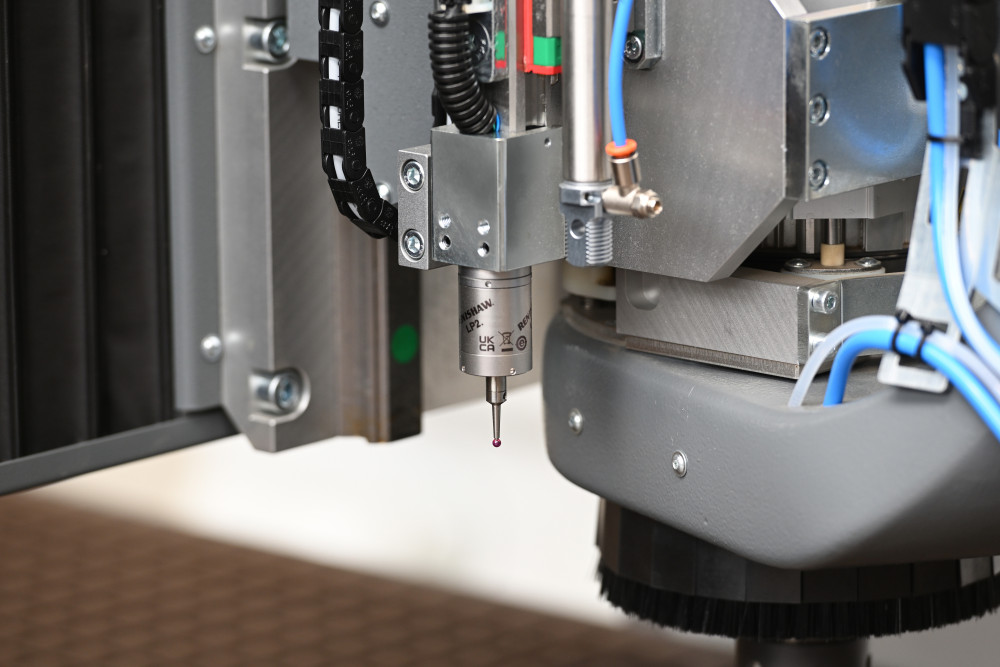

| Automatical correction of the tool lenght | ||

| Panel with control computer | ||

| Oil mist cooling | Automatic | |

|---|---|---|

| Heads | Active, oscillating knife | |

| Creasing | ||

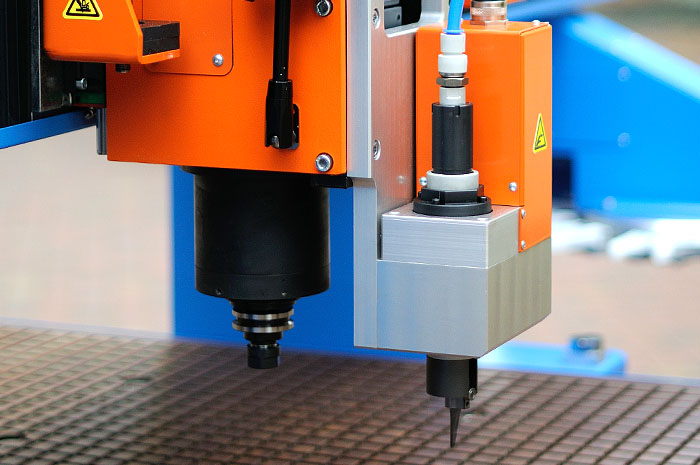

| Active, drag knife | ||

| Knife for cutting film | ||

| Writing | ||

| Pouring | ||

| Scanner | Touch | |

| Laser | ||

| Rotary axis | "B" on the table | |

| "B" inclined spindle | ||

| "C" on the spindle (for angular units) | ||

| Pressure mats | Laser curtains | OHS fence |

| Presser foot | Suction foot | Pressure and suction foot |

| Dust extraction system | Basing system | Camera sighting system |

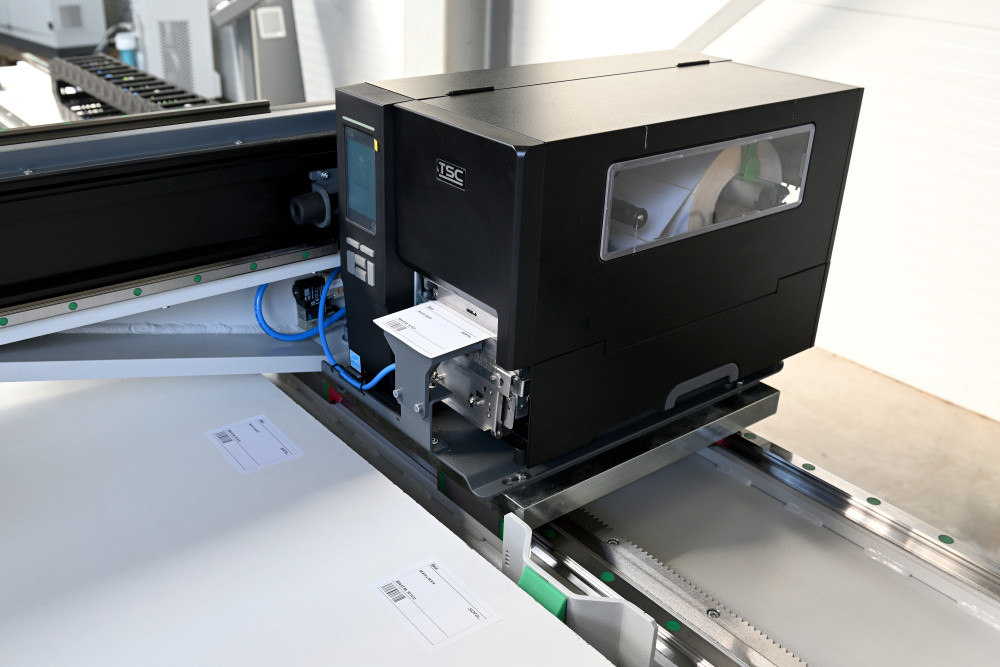

| Detail description printing system | ||

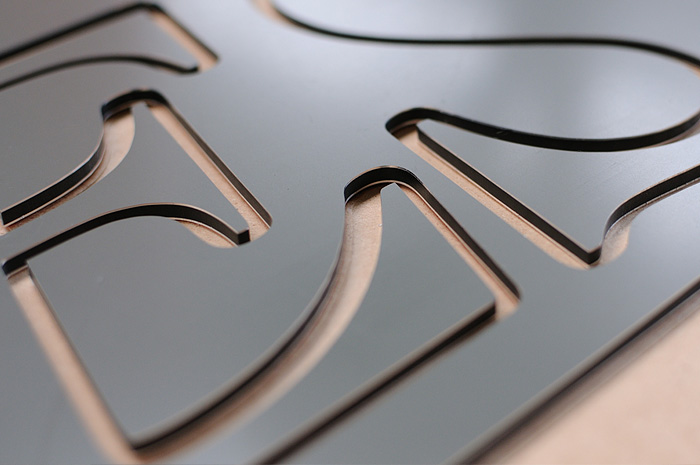

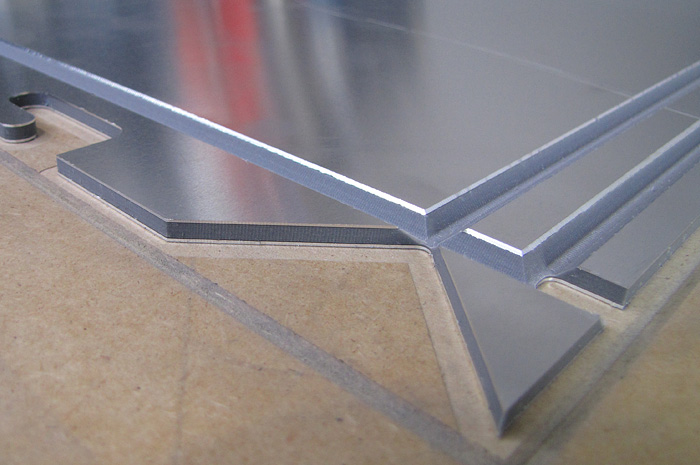

T-Slot Table

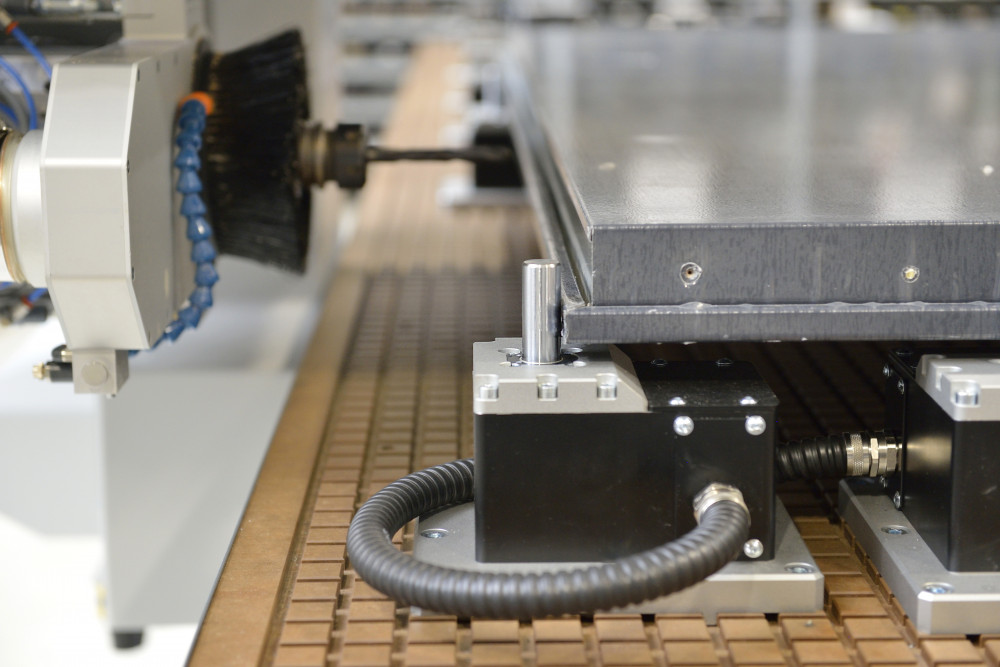

T-Slot Table  Cooling with oil mist

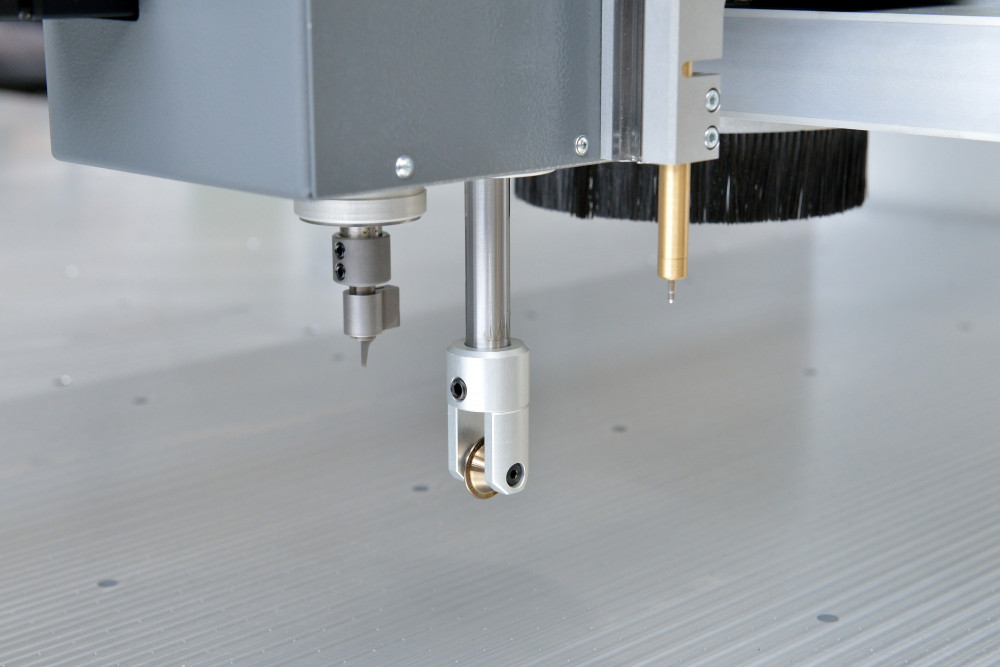

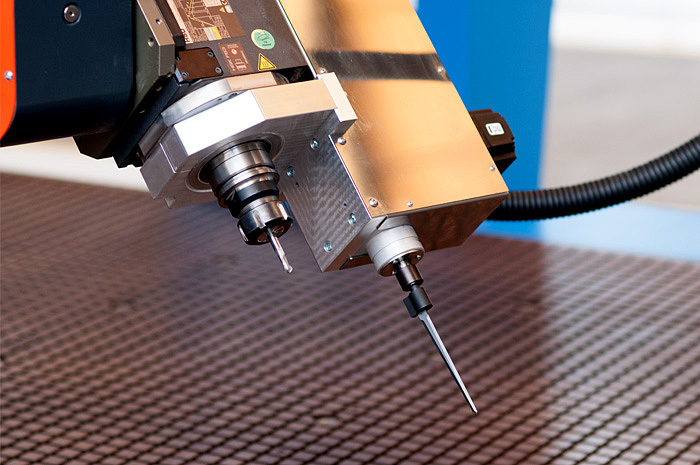

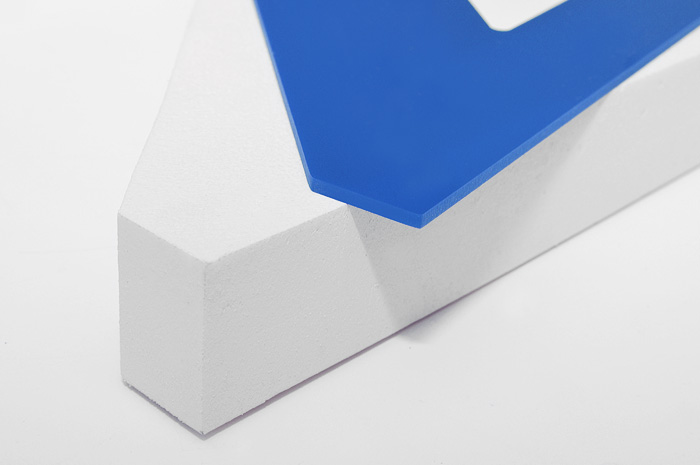

Cooling with oil mist  The tilting axis "C" tilts the spindle

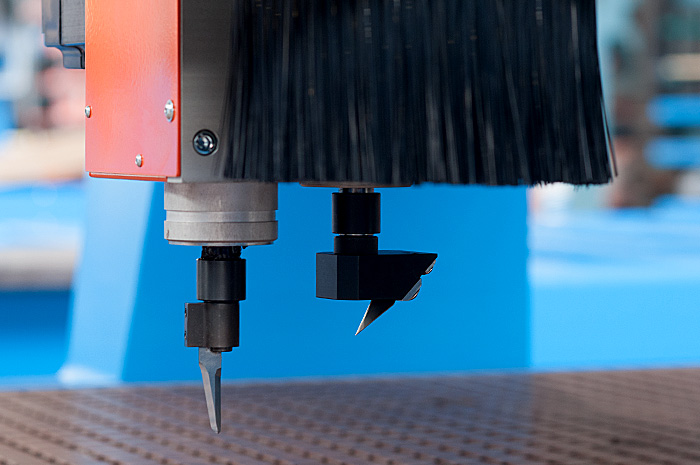

The tilting axis "C" tilts the spindle  Head - active oscillating knife

Head - active oscillating knife  Creasing - Head

Creasing - Head  Writing- Head

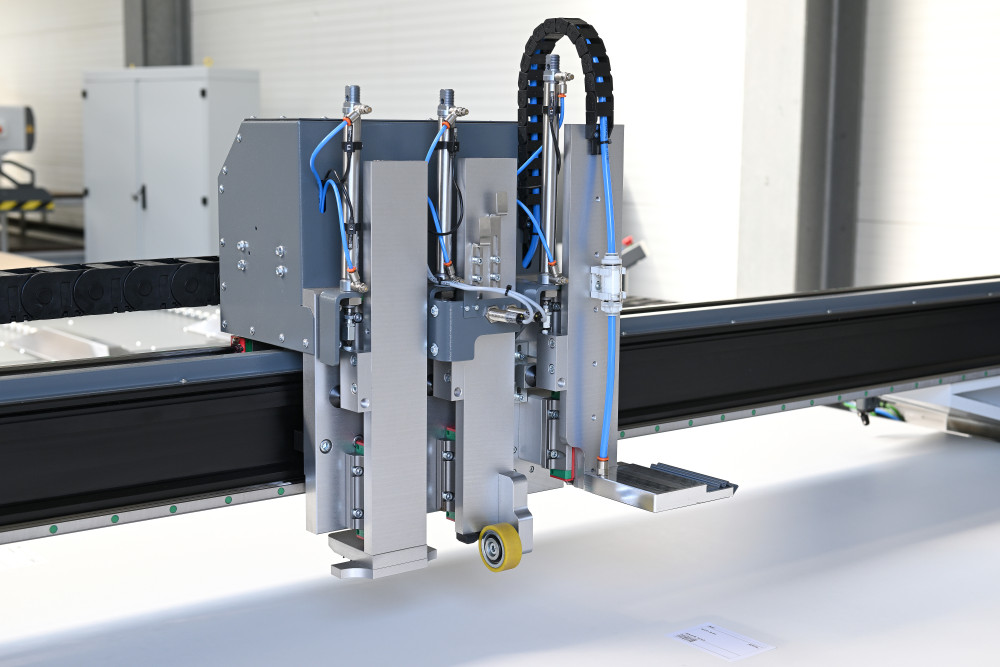

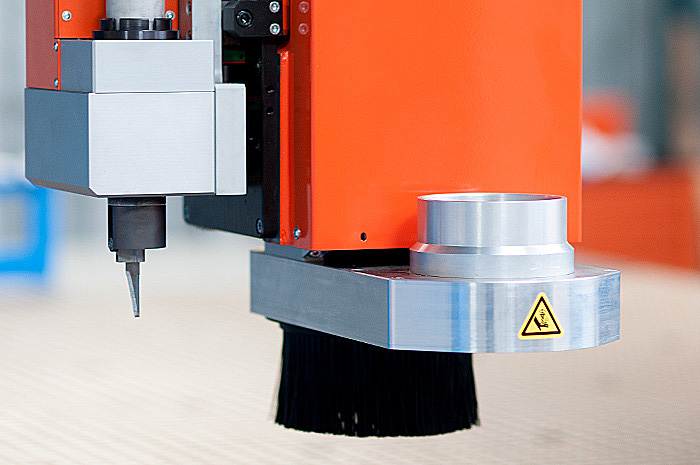

Writing- Head  The presser/extraction foot

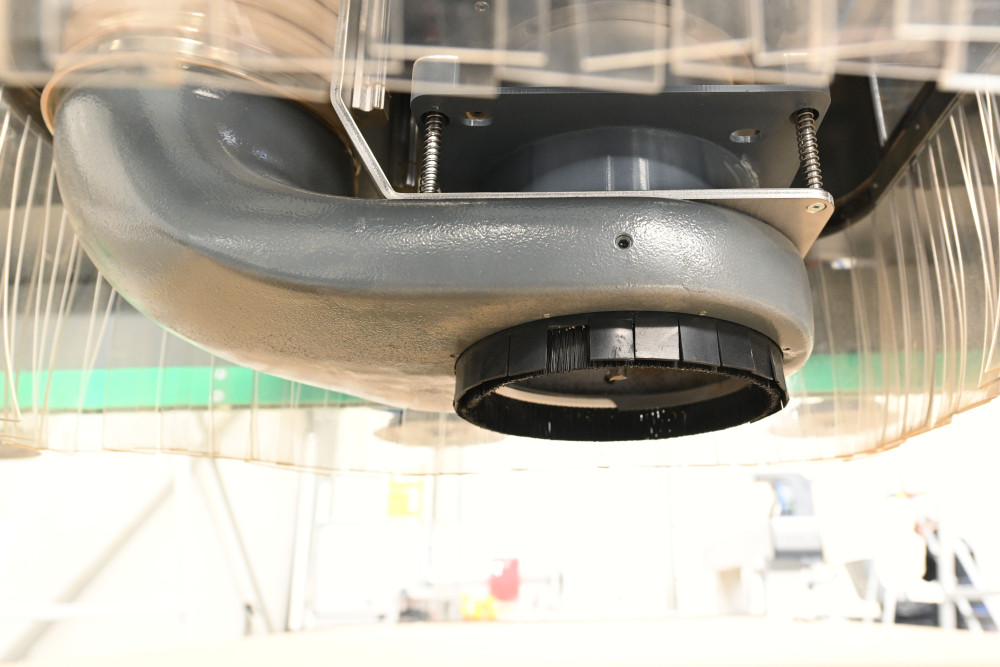

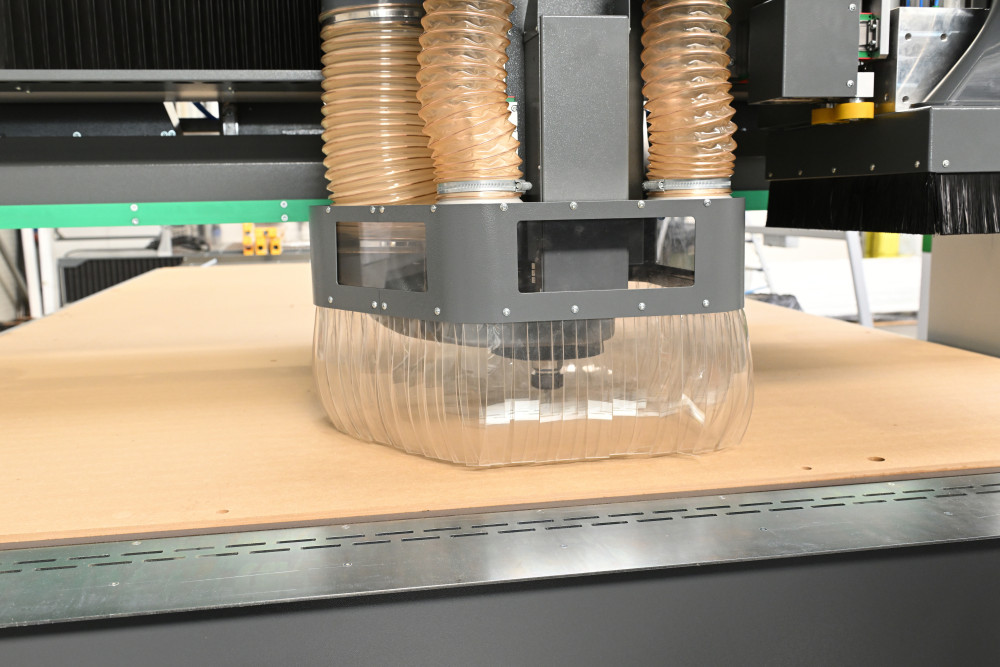

The presser/extraction foot  Dust extraction

Dust extraction  Positioning system

Positioning system  Printing system for parts description

Printing system for parts description  T-slot table

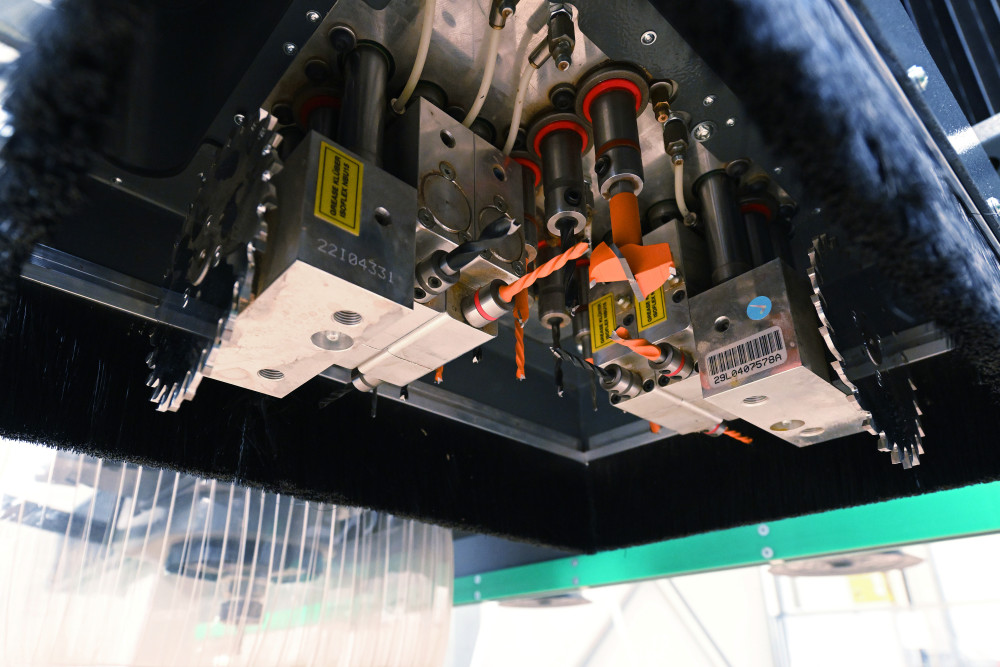

T-slot table  Tool magazine - turret

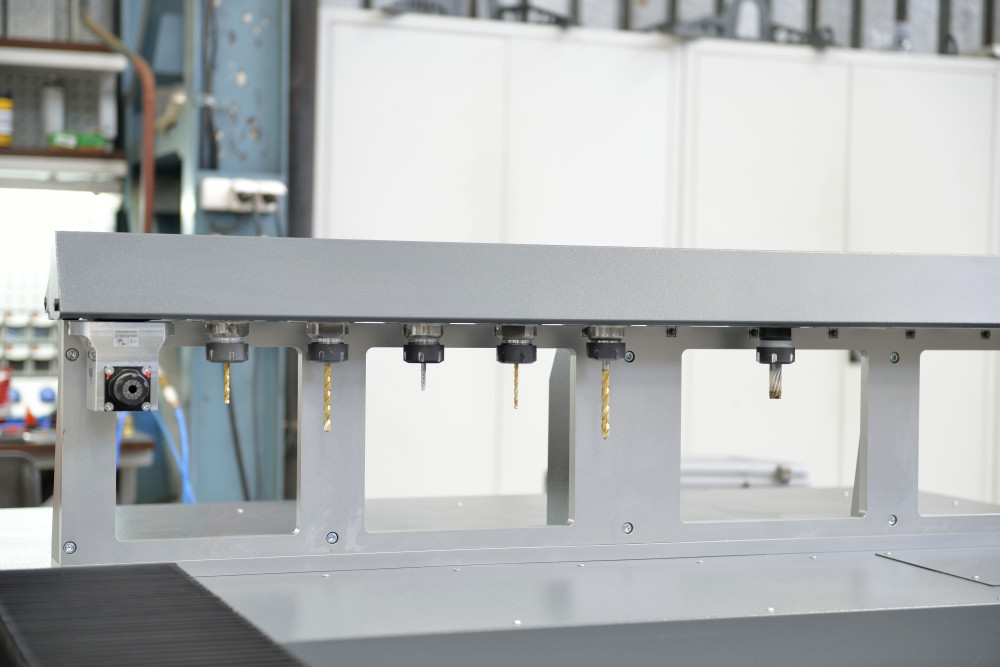

Tool magazine - turret  Tool magazine - linear

Tool magazine - linear  Touch scanner

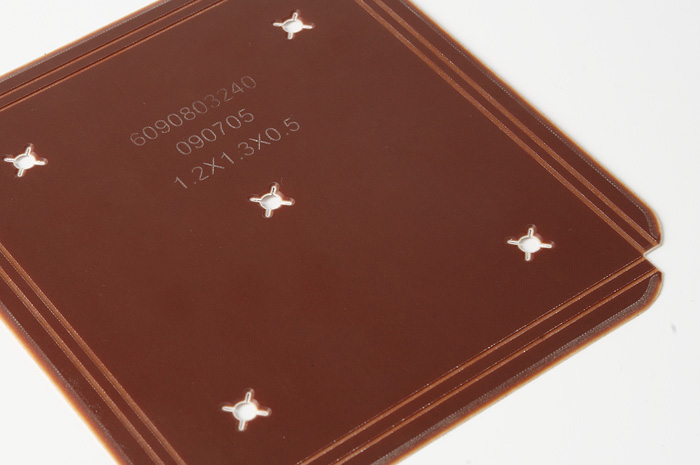

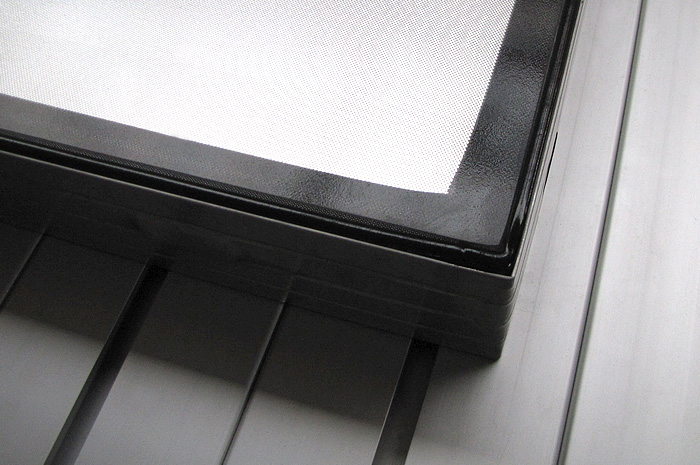

Touch scanner  Underpressure table

Underpressure table  Vacuum table

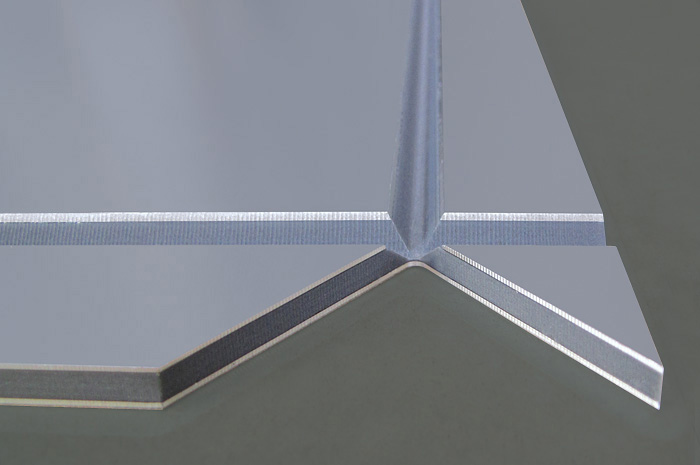

Vacuum table  Hybrid table

Hybrid table  Safety fencing

Safety fencing  Extraction foot

Extraction foot  Laser curtains

Laser curtains  "B" rotary axis on the table

"B" rotary axis on the table  Pressure mats

Pressure mats  Laser curtains

Laser curtains  Presser foot

Presser foot  Camera positioning system

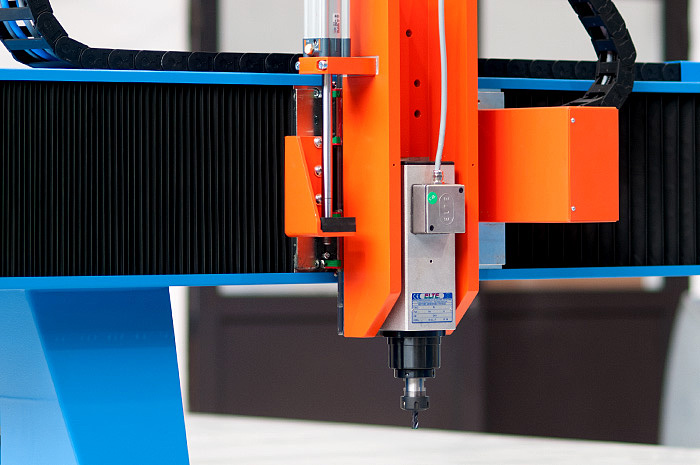

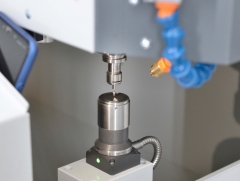

Camera positioning system  Automatic tool length compensation

Automatic tool length compensation  Control panel on aerial arm

Control panel on aerial arm