Machining Centre HSM Linear

HSM Linear machining centre is a machine tool for precision and tool works. It proves useful wherever extremely high positioning precision is required. Instead of the traditional circulating screw used up to now in CNC machines in X Y Z axes, linear drives and measurments system - with the resolution of 1nm and accuracy of 5 micrometers per meterer - were employed.

Linear drives transmit the drive force without friction and contact, solely with the use of magnetic field. Thanks to this, there is no return play, irrespective of the machine's age. The drive doeas not feature wearable parts that could have an effect on the deteroration of milling quality while in operation. In the gantry design of the machine tool with movable table, Kimla company uses solutions that are proved successful and developed for over 20 years.

HSM Linear machining centre is offered with customized working range, as per customer's needs. The standard feature of the device is T-slot work table, sensor of the tool lenght, oil mist colling, high-speed spindle of 7-20kW of power and automatic tool changing with the revolving storage. These solutions provide for highly efficient and precise machining.

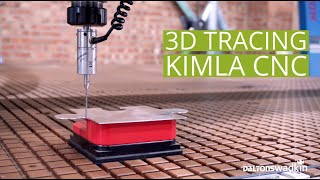

Technological functionality of the machine may be extended through utilisation of additional equipment, e.g. 3D scanning head (for scanning of 2D outlines of 3D object, support for precision basing), rotary axis with poppet-head with full simultaneous interpolation of all axes.

HSM Linear machining centre is designed to machine material, e.g.:steel, aluminium, copper, brass, plastics, composite materials, etc.

Tool Milling Machine Linear

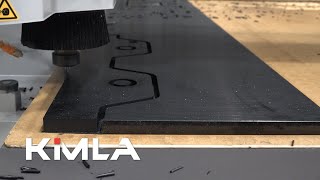

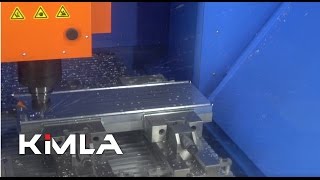

Tool milling machines are devices used for industrial engraving or milling. They are perfect for high-efficiency aluminium machining - both for cutting out sheet metals, as well as aluminium milling from solid plates. The are used also for preparation of extruding, stamping and blanking dies. Most frequently, the machines are equipped with high-speed spindles, liquid-cooled in closed circulation with automatic tool changing. At the same time, the refrigerating unit with cooling liquid temperature stabilization minimizes the effect of spindle's thermal drift. The machines may also be equipped with simple spindle without automatic tool changing when machining works are carried out with one tool and the frequency of tool changes is not high.

As a standard, the tool milling machines are equipped with a booth that secures the work area and oil mist for cooling tools. In the case of larger work areas, the booth is equipped with doors on all sides of the machine. It facilitates free access to the details from any side.

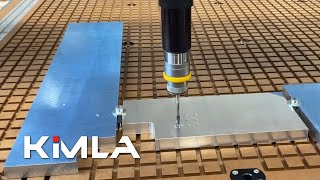

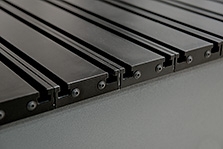

The machines are executed in parallel configuration of kinematics with travelling table. It provides for a very high precision and possibilities of mapping complex paths. CNC tool milling machines may be equipped with T-slot table (standrad) or vacuum table with vacuum pump from the German company Becker, featuring capacity of 40-250 m3/h.

| Working area dimensions [mm] | Width | 700, 1000, 1100, 1300, 1500 ... |

|---|---|---|

| Lenght | 500, 625, 750, 1000, 1250, 1500, 2000 ... | |

| Z axis range | 200, 250, 300, 350, 400, 500, 600 ... | |

| Spindles | 24 000 rpm | 9 kW, 12 kW, 14 kW, 16 kW, 18 kW, 20 kW |

| 40 000 rpm | 5 kW | |

| 50 000 rpm | 3 kW | |

| Control system | Digital AC Servo Drives | |

| Table type | T-slot table | |

| Vacuum table | ||

| Hybrid table | ||

| Automatic tool changing (ATC) | no change | |

| revolver storage | ||

| Automatic correction of the tool lenght | ||

| Colling | Automatic oil mist cooling | |

|---|---|---|

| Scanner | Touch | |

| Laser | ||

| Rotary axis | "B" on the table | |