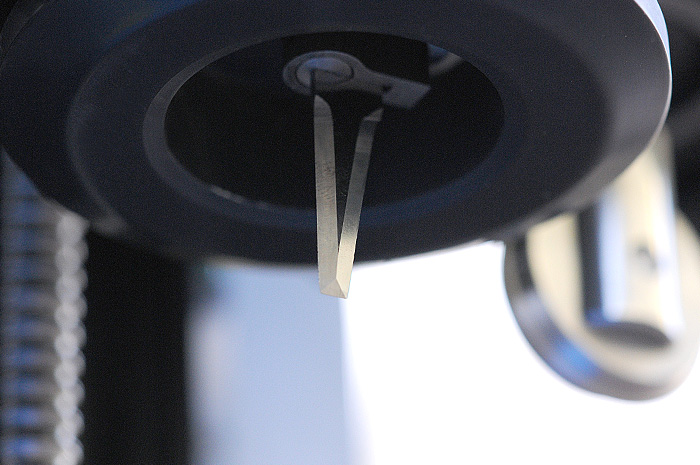

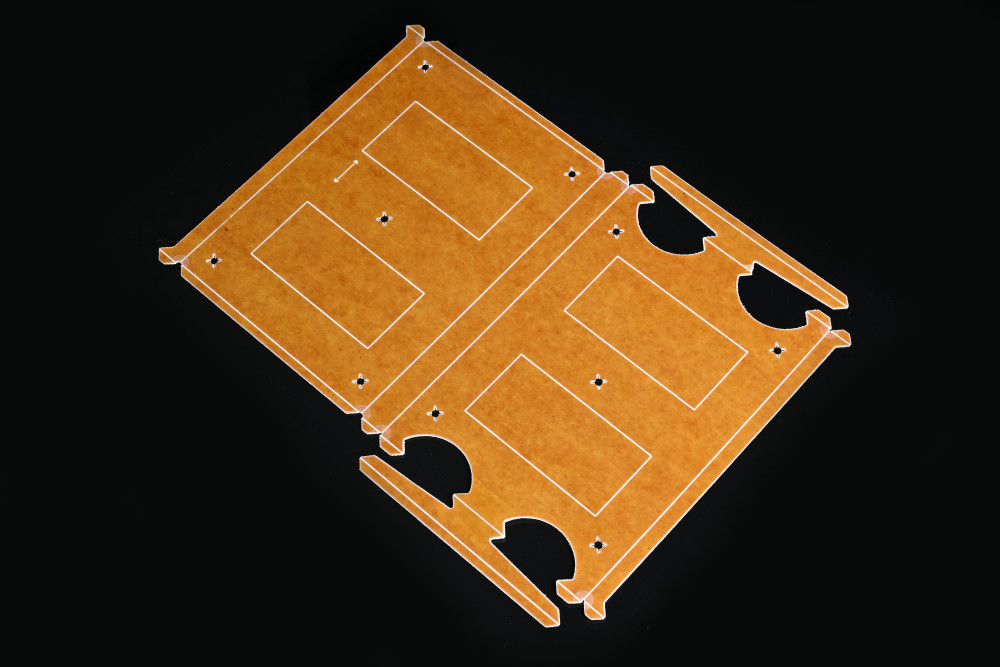

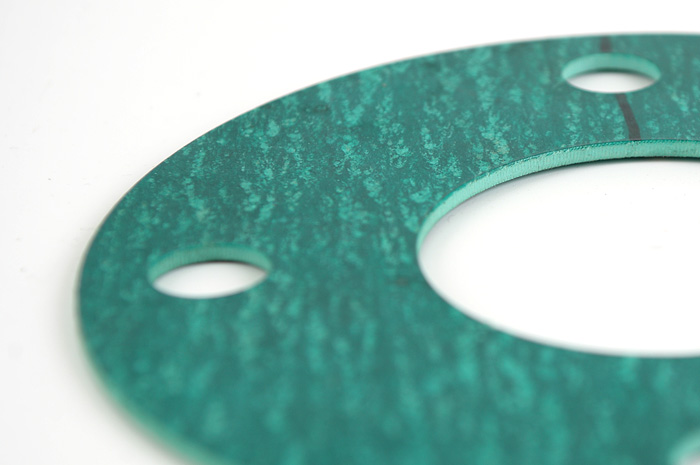

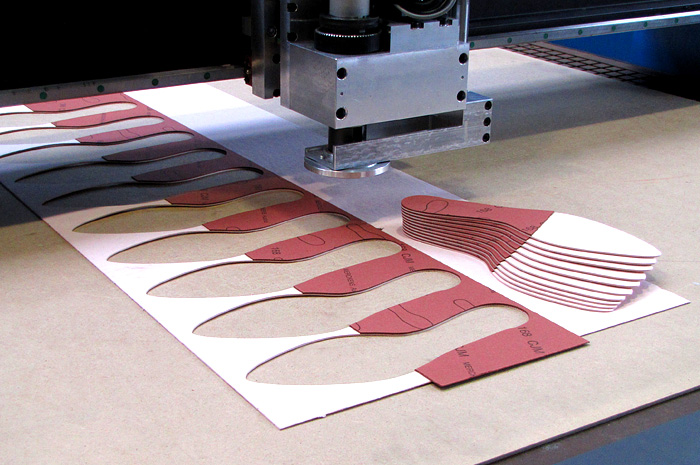

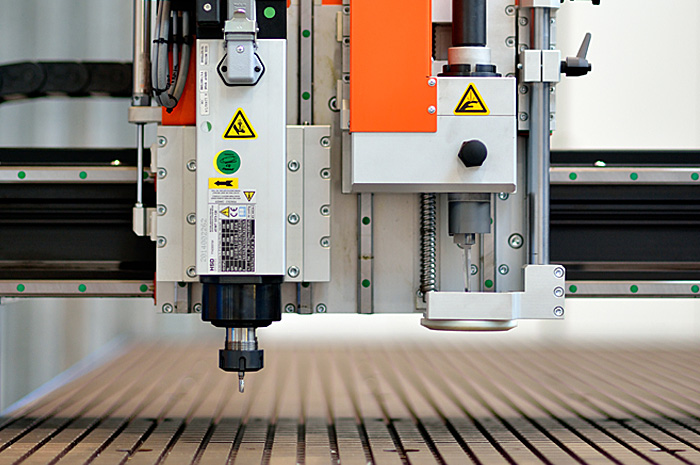

The Kimla universal cnc cutters are machines used for cutting out with oscillating or drag knife. All cutters are equipped with active knife, controlled with servomotors. Machines with oscillating knifes may be furnished with pneumatically or electrically driven heads. Pneumatic heads are high-frequency heads, providing for very high travel speeds in softs materials. Pneumatic heads are used for highly efficient machining of foamed materials of little density. For machining of harder materials and of higher density, e.g.:sealand material, also reinforced with net and steel sheet, the electric heads are recommended that-thanks to employment of two servomotors-feature a very high power. One servomotor is used for adjisting the angle od the knife, and the other one for driving oscillating movement. The unique head power may be obtained through usage of 0.4 kW motor. It allows for performance of production works in different materials, even the ones that once used to be considered impossible to be machined with a cutter.

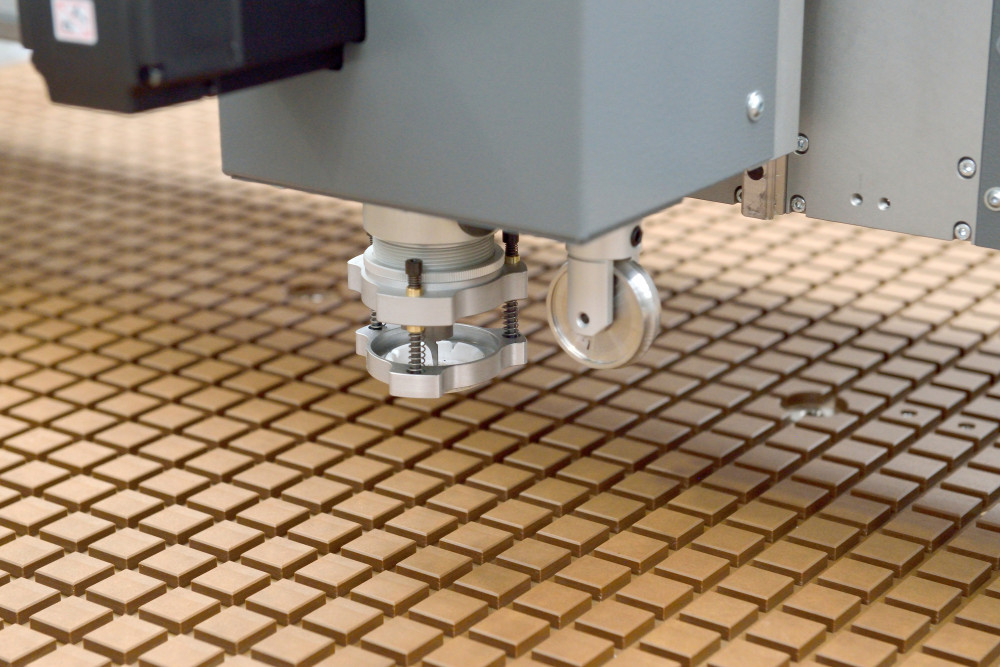

The universal cutter is employed also in single-layer or multiple-layer cutting of fabrics. The materials are fixated on negative pressure or vacuum tables, divided into sections, thus facilitating works in many works areas.

All machines are equipped with control panels with industrial control computer, together with the proper software. The software, except for controilling machines, allows for preparation of tool path and optimal nesting. It caters for maximum usage of the material within a very short preparation period.

| Range area [mm] | Width | 1800, 2200, 2700, 3200 ... |

|---|---|---|

| Lenght | 1600, 2100, 2500, 3100, 4100, 5100, 6100 ... | |

| Z axis range | 200 | |

| Oscillating Knife | Pneumatic | |

| Electric 1x servo, 2x servo | ||

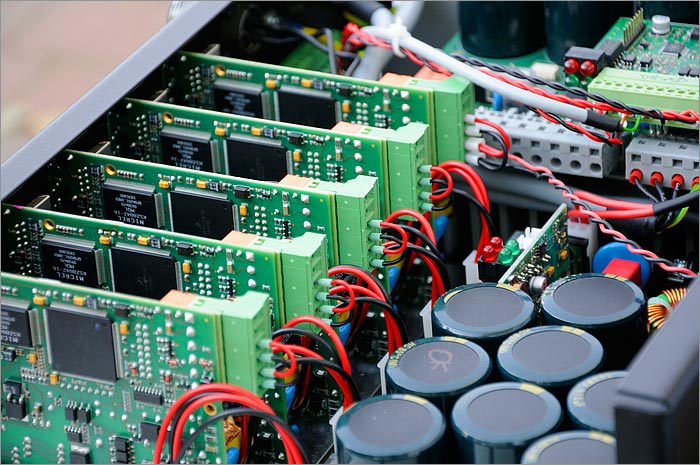

| Drive system | Linear Drives(High Speed) Digital Servo Drives AC High Speed | |

| Table type | Vacuum table | |

| Control computer | ||

| Heads | Milling head (spindle) | |

|---|---|---|

| Creasing head | ||

| Marking head | ||

| Writing head | ||

| Scanner | Touch | |

| Laser | ||

| Joystick control | ||

| Safety mats | ||

| Basing system | ||

| Conveyor system | ||

| Receiving table and loading | ||

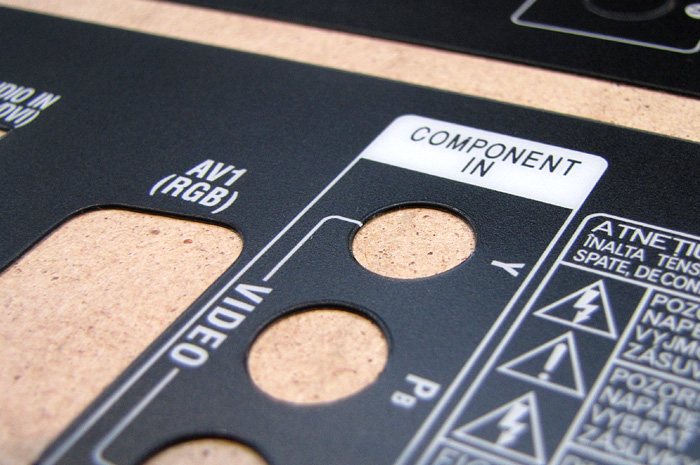

Writing- Head

Writing- Head  Descriptions printing system on details

Descriptions printing system on details  Camera targeting system

Camera targeting system  Health and safety fencing

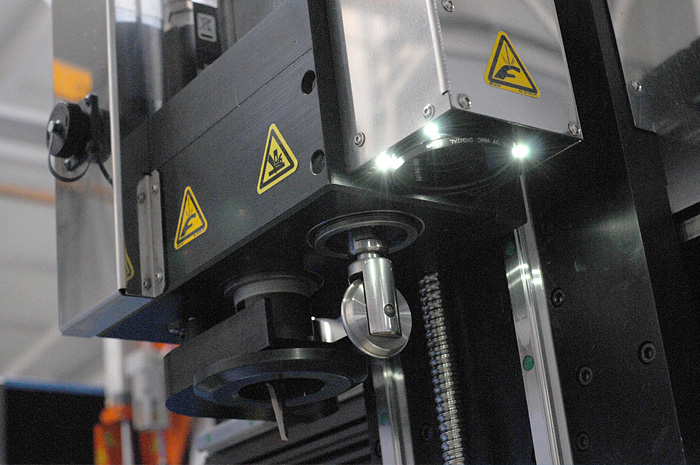

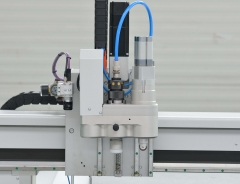

Health and safety fencing  Electric oscillating knife 2x servo

Electric oscillating knife 2x servo  Pneumatic oscillating knife

Pneumatic oscillating knife  Control cabinet with a computer

Control cabinet with a computer  Writing head

Writing head  Creasing head

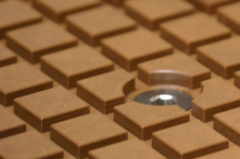

Creasing head  Vacuum table

Vacuum table  OHS safety barriers with a laser beam

OHS safety barriers with a laser beam  Desktop with control computer

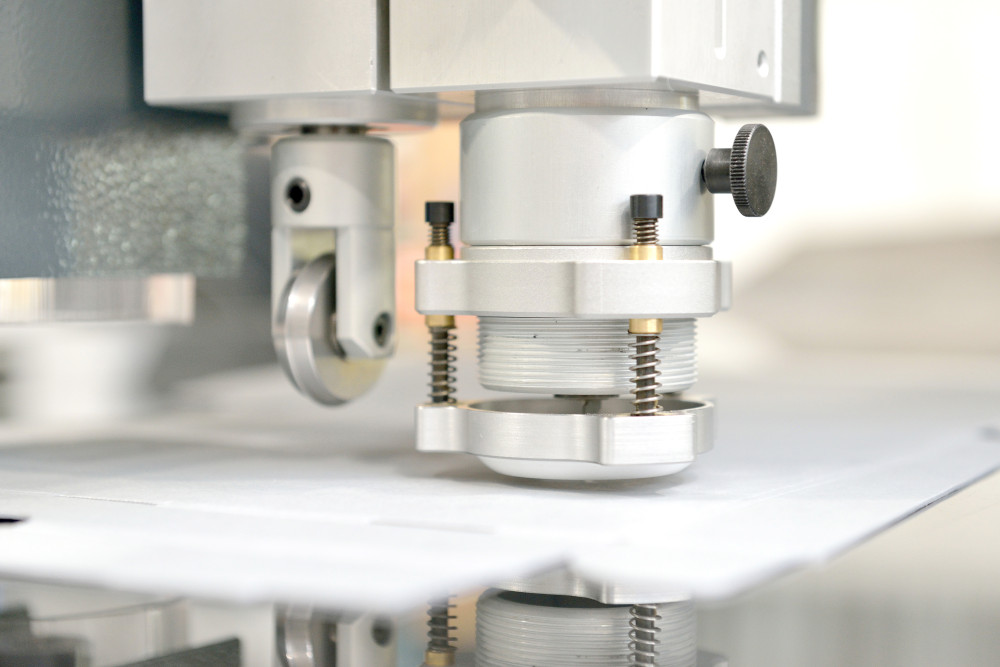

Desktop with control computer  Automatic tool length compensation

Automatic tool length compensation  Homing system

Homing system  Chip extraction

Chip extraction  Laser curtains

Laser curtains  Oil mist cooling

Oil mist cooling