The oscillation is driven by pressurized air supplied to the machine. The oscillation speed and force are regulated by airflow control and cannot be fine-tuned from the computer. The head is characterized by a very high oscillating speed, thanks to which it is possible to cut materials with very high efficiency. Due to the way vibrations are generated...

A set of posts placed around the machine to detect the presence of people approaching it. They cause the device to stop working when the laser beam is exceeded. The set consists of a transmitter, a receiver and two reflecting mirrors, which ensures the machine is secured up to three sides.

A set of posts placed around the machine to detect the presence of people approaching it. They cause the device to stop working when the laser beam is exceeded. The set consists of a transmitter, a receiver and two reflecting mirrors, which ensures the machine is secured up to three sides. Contrary to laser barriers, they have more densely placed laser beams, which enable faster reaction to human intrusion into the machine's operating zone.

System of minimum lubrication with air-oil mixture fed to the cutting zone. It replaces the traditional, uneconomical cooling systems of the treatment zone based on emulsion solutions. Before the outlet nozzle, the air, supplied under pressure, mixes with the oil dosed in the volume of a few drops per minute...

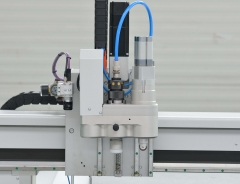

This head is characterized by a very high oscillation force. Thanks to this, it is possible to cut through materials that offer very high resistance, as well as materials with a large thickness. With the use of an appropriate blade, it is possible to cut rubber with a thickness of up to 30mm. The oscillation speed is regulated by setting the desired value from the program in the range from 0 to 5000 movements per minute. If the value is set to 0, the blade automatically moves to the maximum forward position and the head performs work without oscillation. A speed range of about 1000 strokes per minute is typically used to make perforations in cardboard.

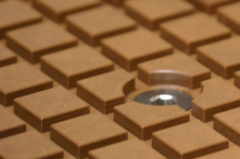

A set of mechanical bases placed on the machine table, ensuring repeatability of the arrangement of the given material (usually boards). The operator, when placing the material on the table, pushes it against the protruding pins, thanks to which it is placed in the right place. This solution helps with large-scale production of elements.

The tool correction sensor enables automatic input of the tool length correction value mounted in the CNC chuck or directly in the spindle. The machine tool automatically measures the length of the tool, then corrects the Z axis coordinate so that the end of the tool is at the appropriate height. In machines equipped with an automatic tool change, the measurement may be performed once or before each use. It is also possible to measure the tool after machining to check for damage.

The console placed on the arm and attached to the CNC machine replaces the previous solution in the form of a control cabinet and has a more ergonomic structure. The desktop includes: an industrial PC computer, which is the interface of the machine, along with a monitor, keyboard and mouse, while the controller, inverter, etc. in this case they were transferred to the machine body.

A control cabinet with a control panel adapted to a given machine tool, equipped with a functional drawer for small CNC accessories, tools, keys, etc. Tight, ventilated structure, made of 1.5 mm thick, powder-coated steel sheet. The installed wheels with a blockade allow you to adjust the position of the desk within a few meters to the setting of the machine and ensures ergonomics of the station.