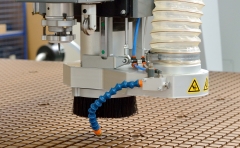

System of minimum lubrication with air-oil mixture fed to the cutting zone. It replaces the traditional, uneconomical cooling systems of the treatment zone based on emulsion solutions. Before the outlet nozzle, the air supplied under pressure mixes with the dosed oil.

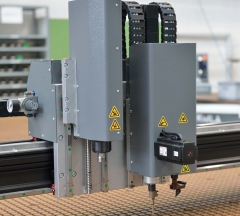

A control cabinet with a control panel adapted to a given machine tool, equipped with a functional drawer for small CNC accessories, tools, keys, etc. Tight, ventilated structure, made of 1.5 mm thick, powder-coated steel sheet. The installed wheels with a blockade allow you to adjust the position of the desk within a few meters to the setting of the machine and ensures ergonomics of the station.

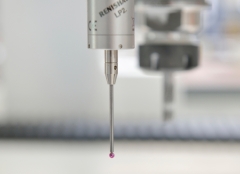

The touch scanning head is used, inter alia, to scan details in order to make duplicates or enter into the computer memory for further processing. It allows you to scan uneven surfaces and take into account its deflection when designing. It can also be used as a probe for basing on plates, in holes, on cylinders and for scanning three-dimensional objects for digitization. It is available in a wired version - mounted manually, lowered automatically on the Z axis and in a wireless version - taken from the tool magazine.

This head is characterized by a very high oscillation force. Thanks to this, it is possible to cut through materials that offer very high resistance, as well as materials with a large thickness. With the use of an appropriate blade, it is possible to cut rubber with a thickness of up to 30mm. Adjustable oscillation speed.

The head is used together with the cutting head (electric or pneumatic), allowing to make special bends, usually on the cardboard, enabling the material to be bent later. Usually, this head uses creasing wheels of various diameters and widths, as well as other tools, e.g. V-cut heads.

Dodatkowa głowica, zamontowana obok głowicy tnącej/frezującej, pozwalająca na znakowanie obrabianego detalu. Posiada własny siłownik, dzięki czemu opuszcza się automatycznie. Może służyć zarówno do nanoszenia opisów na detalach, jak i do rysowania zadanych kształtów.

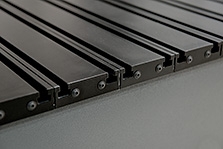

A set of mechanical bases placed on the machine table, ensuring repeatability of the arrangement of the given material (usually boards). The operator, when placing the material on the table, pushes it against the protruding pins, thanks to which it is placed in the right place. This solution helps with large-scale production of components ...